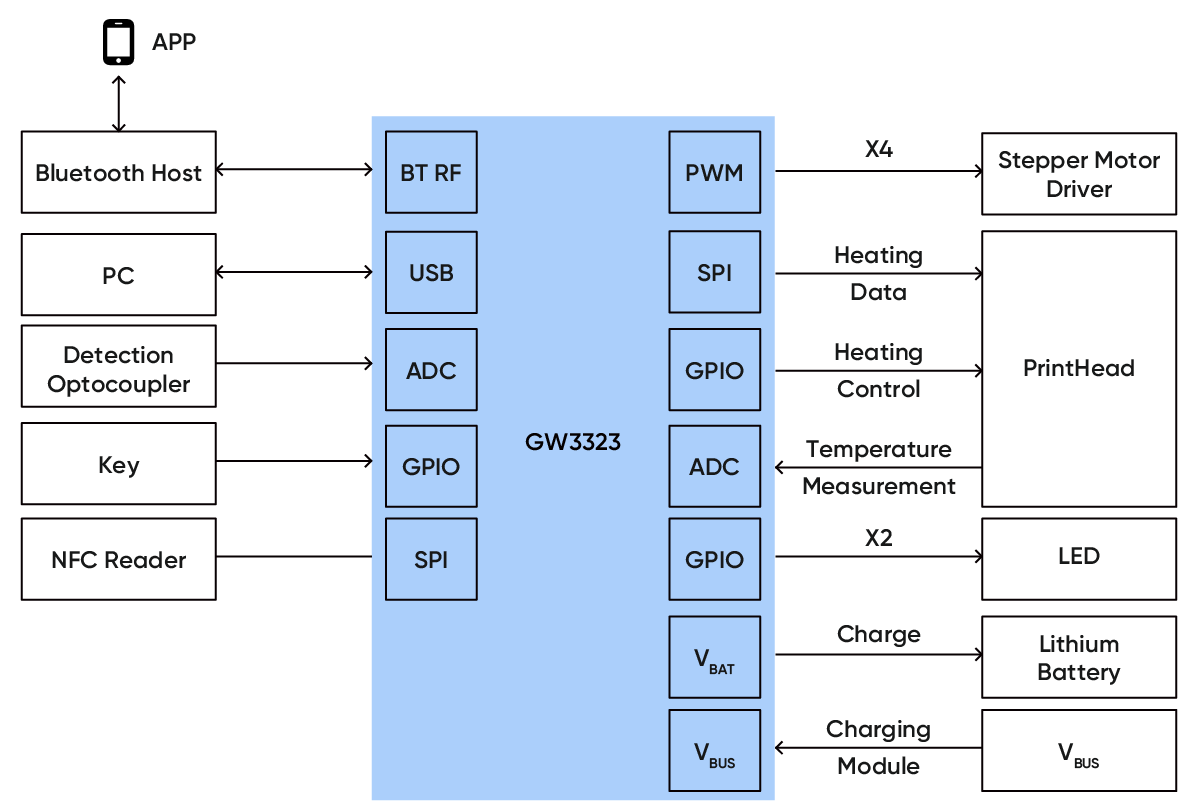

It is mainly composed of a control circuit, stepper motor driver, thermal film, human-machine interaction, and peripheral circuit. The MCU in the control circuit is used to dynamically process the image characters and control the peripheral devices. The MCU receives the print command and subsequently sends the dot matrix data to the print head through the SPI interface to complete the data conversion while detecting the print head temperature and controlling the stepper motor for precise paper rolling, key presses, and other operations.

As one chip can realize Bluetooth phone pairing and thermal printer control, the solution is very cost-effective and can be used for labeling groceries, household items, and cables. With rich interfaces and reliable transmission, the master chip can effectively guarantee stable output and no need for multiple serial interrupt services. The ADC determines whether overheat protection is needed by detecting the thermistor value and whether the paper is running out by detecting the optocoupler output.