As the global energy mix shifts toward cleaner,low-carbon development,PV power generation continues to expand as a core renewable resource. However,solar panels operate outdoors year-round,and contaminants such as dust, sand, and bird droppings reduce light transmittance, causing a 5%–30% loss in power output.

Traditional manual cleaning is inefficient, costly, and unsafe, especially for large solar farms. To address these challenges, solar panel cleaning robots have emerged. With automated and intelligent cleaning capabilities, they have become essential for maintaining PV performance, improving O&M efficiency, and reducing lifecycle costs.

Rapid Growth in the Solar Panel Cleaning Robot Market

Driven by carbon-neutrality targets and surging solar panel installations, the solar panel cleaning robot market is entering a period of rapid expansion. Industry data shows a global market size of USD 1.5–2 billion in 2023, expected to surpass USD 5 billion by 2030, with a CAGR of 18%–22%.

Core Architecture of Solar Panel Cleaning Robots

▪ Mobility System:

The "legs," enabling autonomous navigation with precision wheel or track mechanisms.

▪ Cleaning System:

The "hands," using brushes, spray modules, squeegees, or vacuums to remove contaminants.

▪ Perception System:

The "eyes," relying on sensors to detect panel boundaries, obstacles, and contamination levels.

▪ Control System:

The "brain," performing path planning and coordinating multi-module operations.

▪ Power Management:

The "heart," supporting battery power, charging, and long-duration use.

Among these, the control system defines intelligence, stability, and overall cleaning performance. As its core, the MCU plays a decisive role.

Geehy's Three-Chip Solution Builds a Powerful "Heart" for Solar Panel Cleaning Robots

To meet application requirements, Geehy offers a "Control + Motor + Driver" chip combination that delivers high performance, high efficiency, and strong reliability for professional solar cleaning robots.

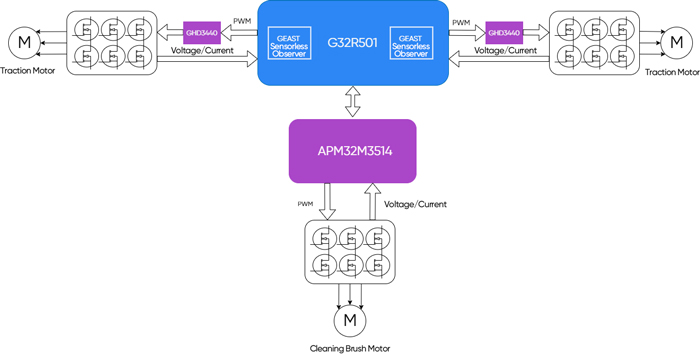

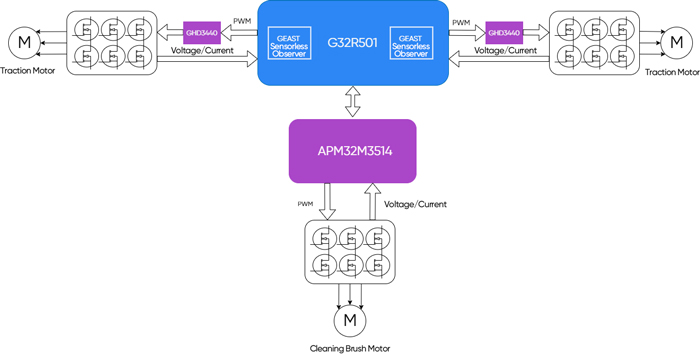

Solar Panel Cleaning Robot System Block Diagram

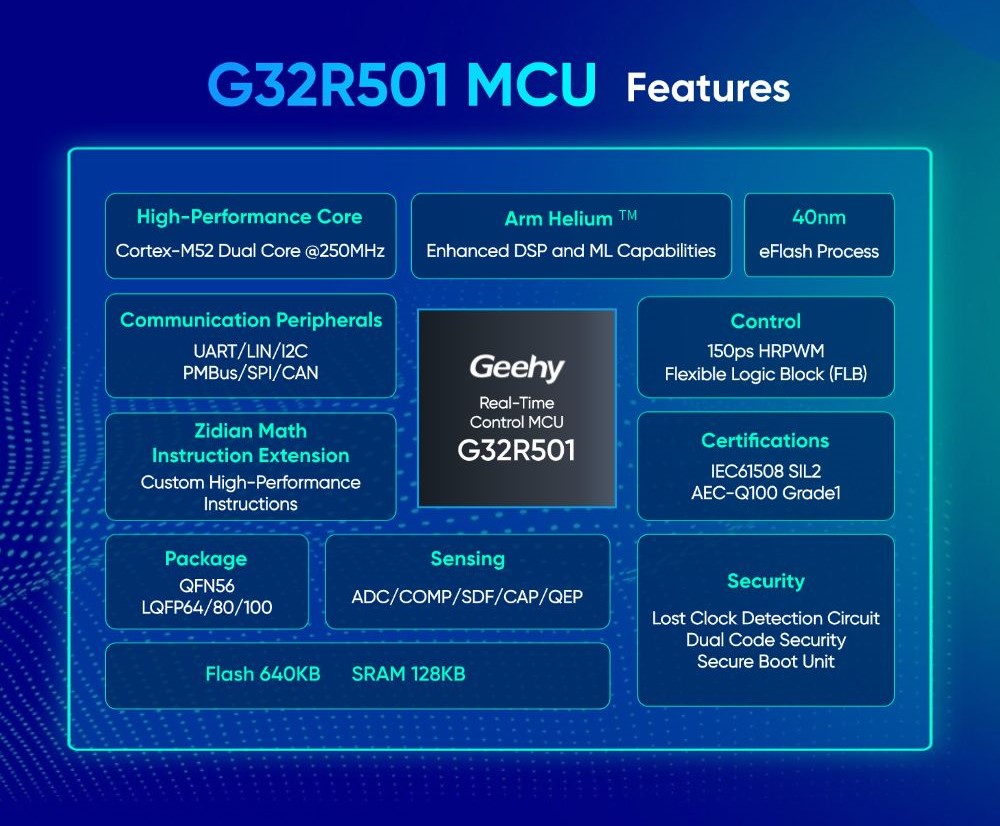

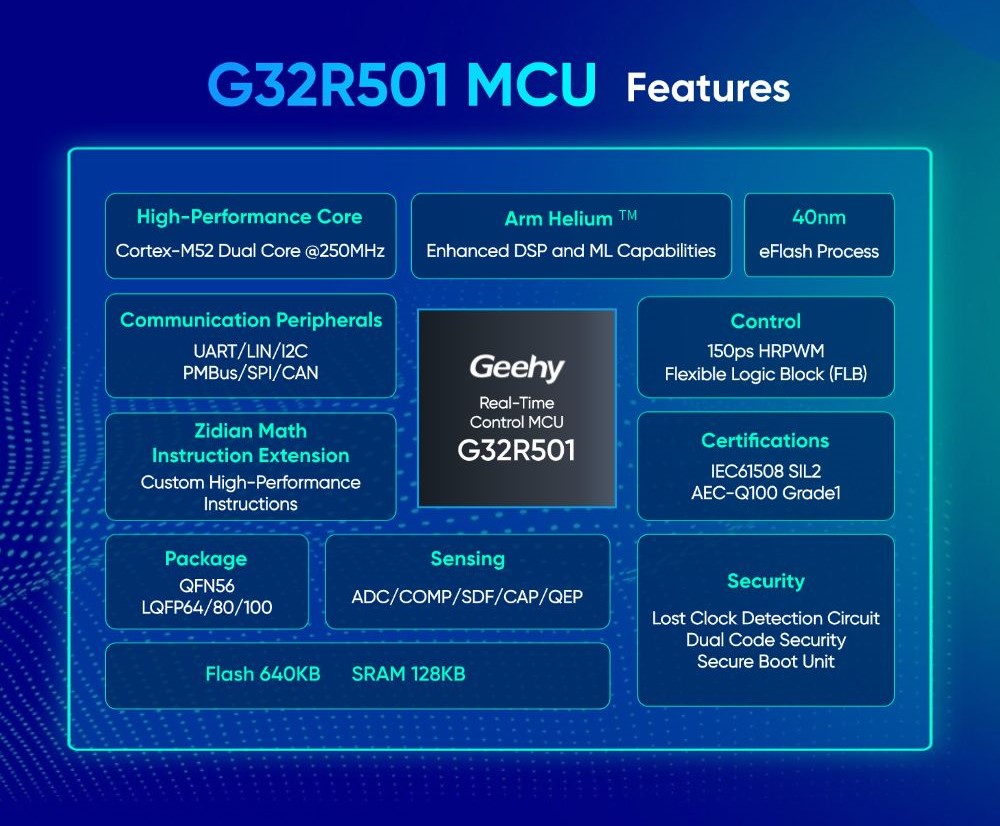

G32R501 Real-Time MCU Intelligent Core with Edge AI Acceleration

As the main control processor, the G32R501 manages mobility, including linear motion, turns, and obstacle traversal, and processes sensor data to optimize cleaning actions in real time. Its dual-core Cortex-M52 architecture, running up to 250MHz, enables rapid response, advanced path planning, and multi-task scheduling.

For dual-wheel control, the G32R501 supports FOC motor algorithms for precise torque and speed adjustment. With the integrated GEAST sensorless observer, it estimates rotor position without external sensors, reducing cost and improving robustness. The built-in Helium™ edge-AI accelerator and Geehy's Zidian instruction extension further enhance motion planning, improving cleaning efficiency by up to 40% compared with conventional systems.

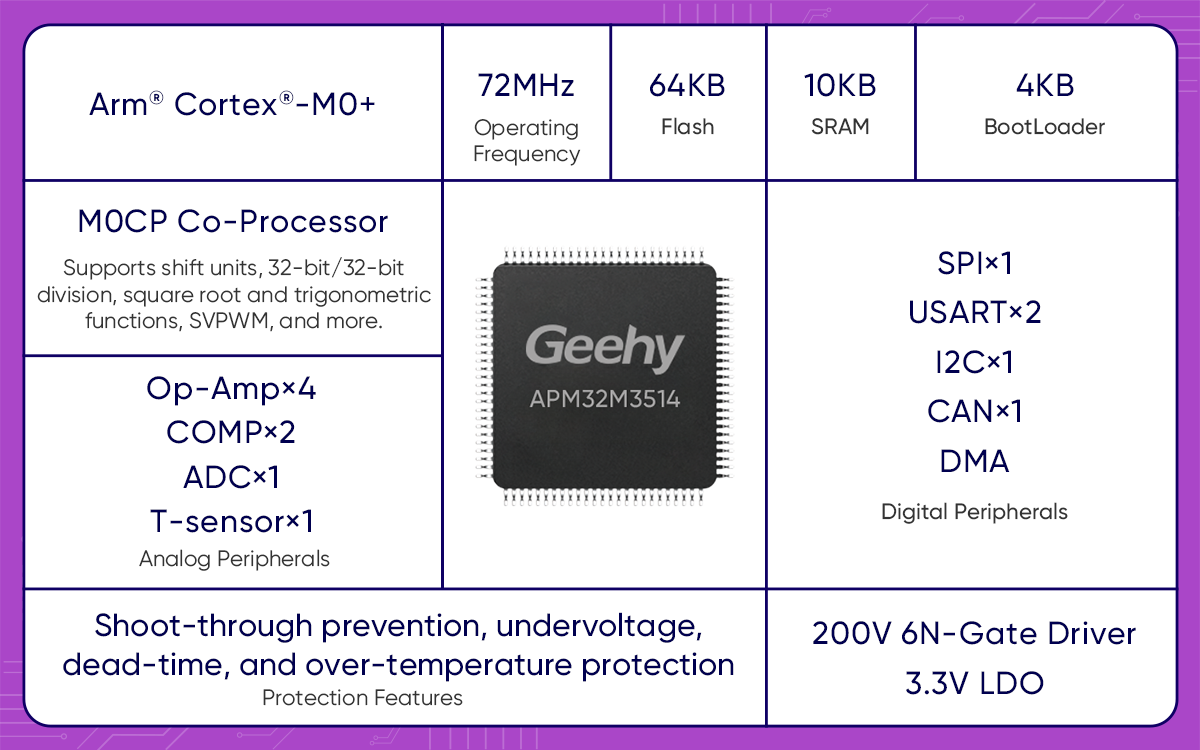

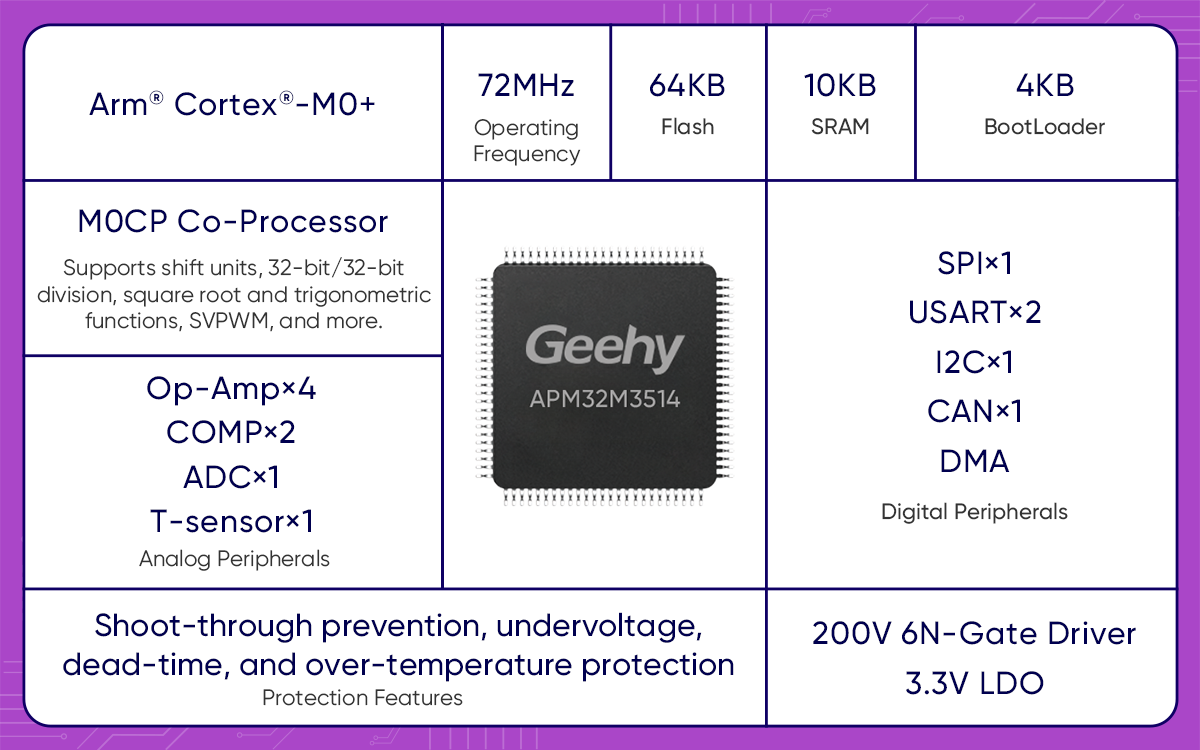

APM32M3514 Motor Control SoC Power Execution with Precision

The APM32M3514 controls the cleaning brush motor and features a Cortex-M0+ core running at 72MHz. Equipped with the M0CP hardware accelerator and Geehy's algorithm ecosystem, it delivers precise torque and speed regulation to maintain effective cleaning while protecting panel surfaces.

Integrated 3.3V LDO, rich analog resources, and hardware protections, including over-current and over-temperature, ensure fast response, safety, and stable motor-drive performance.

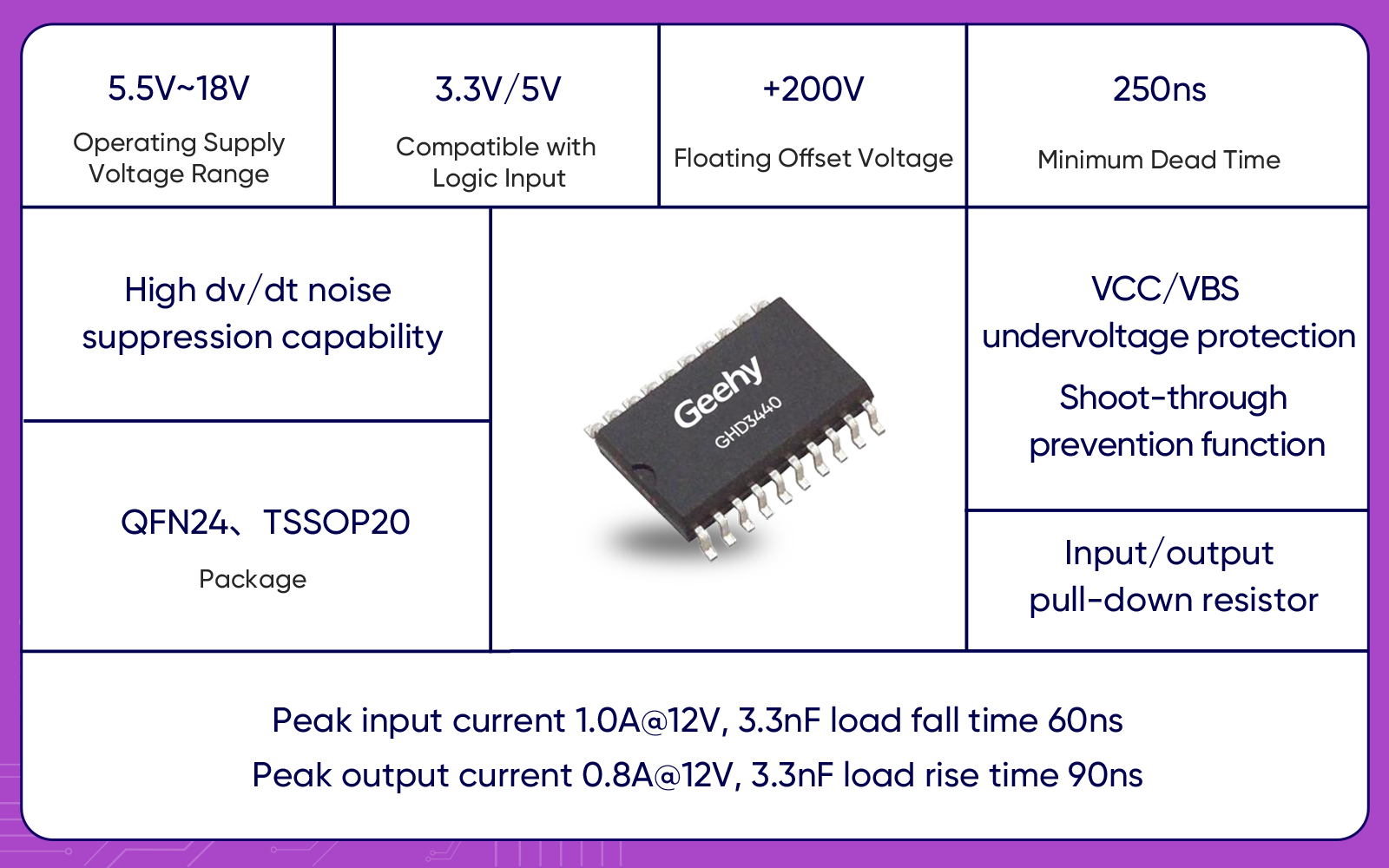

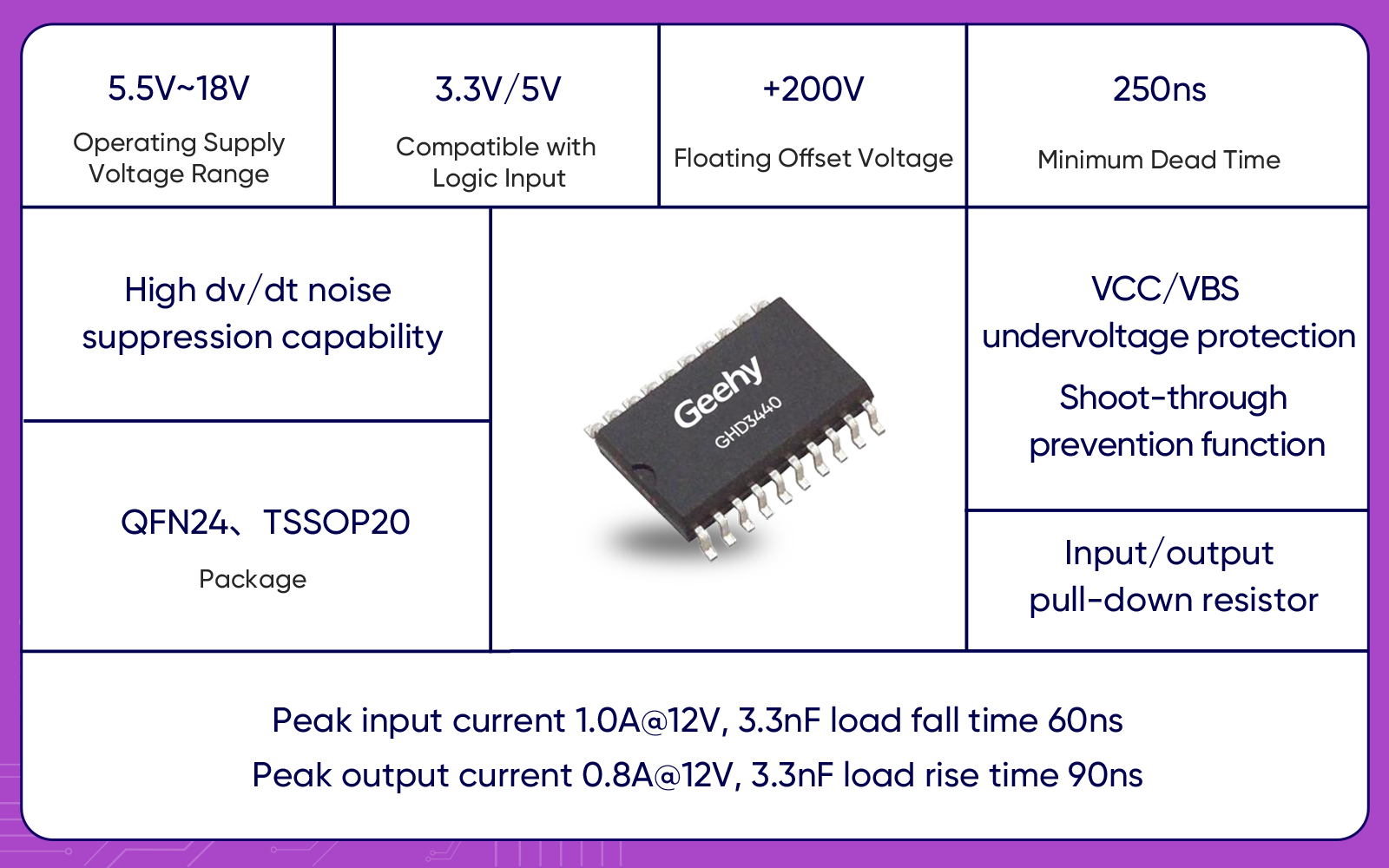

GHD3440 Gate Driver High-Power Output with Robust Protection

The GHD3440 is a 200V dual-N-channel three-phase gate driver designed for traction and cleaning motors. It converts MCU/SoC control signals into high-drive currents for MOSFETs, enhancing drive efficiency and motion stability.

Its dual-channel structure, 3.3V/5V logic compatibility, and strong drive capability support high-voltage and high-current applications. Built-in features such as a 250ns deadband, undervoltage protection, and shoot-through prevention further enhance system safety.

From large desert solar panel plants to commercial rooftop arrays, solar panel cleaning robots are becoming essential for maintaining clean-energy output. Geehy's integrated solution, G32R501 + APM32M3514 + GHD3440, provides high performance, high integration, and strong reliability to accelerate intelligent, efficient, and energy-saving solar panel maintenance.

Looking ahead,Geehy will continue to drive semiconductor innovation in the energy sector, supporting the global clean-energy transformation and long-term sustainable development.