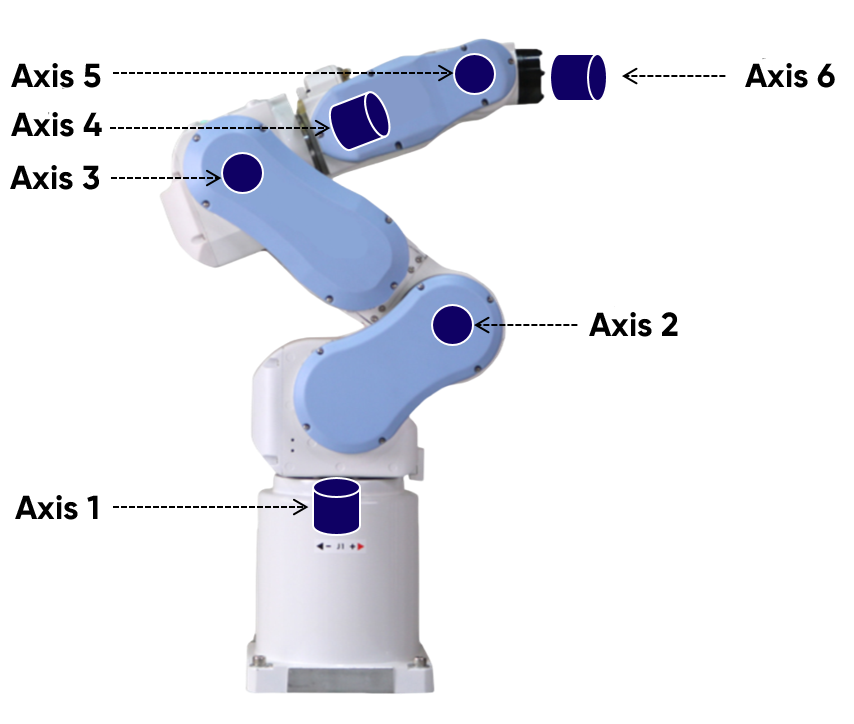

As Industry 4.0 continues to reshape global manufacturing, six-axis robotic arms have become essential for modern automation. Known for their precision, flexibility, and adaptability, these robotic arms are widely applied in automotive assembly, industrial automation, healthcare, logistics, and food processing. With the ability to perform complex, high-precision tasks in dynamic environments, six-axis robots are a cornerstone of smart manufacturing. According to Grand View Research, the global industrial robotics market is expected to reach USD 34 billion by 2024, with a projected Compound Annual Growth Rate (CAGR) of 9.9% from 2025 to 2030.

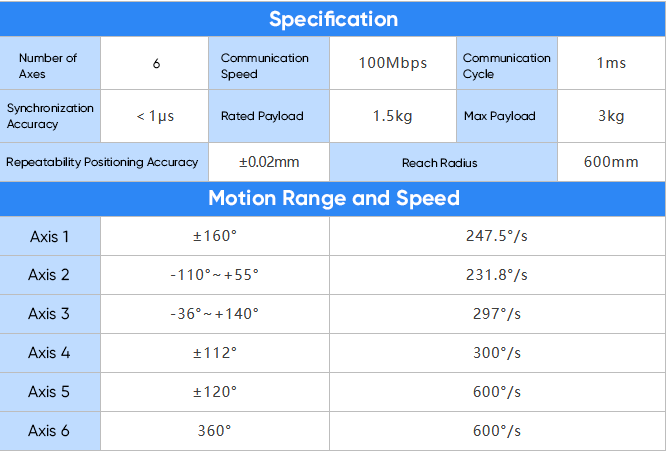

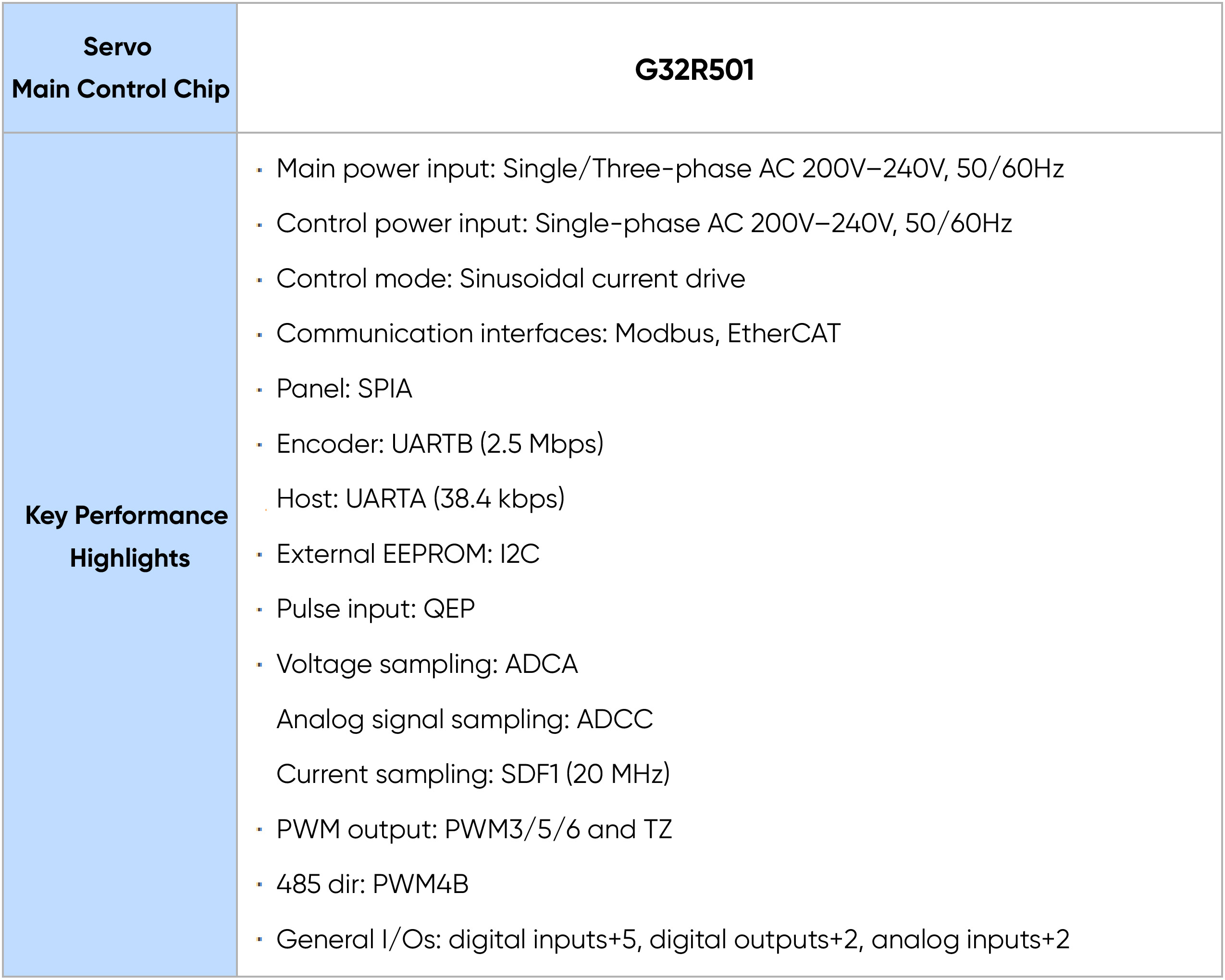

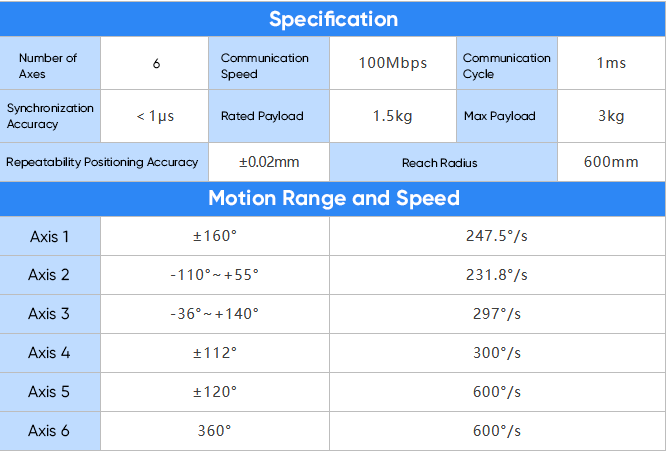

Geehy's six-axis robotic arm solution features the high-performance G32R501 real-time MCU as the servo control core, delivering microsecond-level response and advanced motion control. By integrating cost-effective EtherCAT industrial Ethernet, the solution achieves precise, real-time, multi-axis coordination, ideal for demanding applications such as welding, palletizing, and painting.

Programmable Control System

for Greater Flexibility

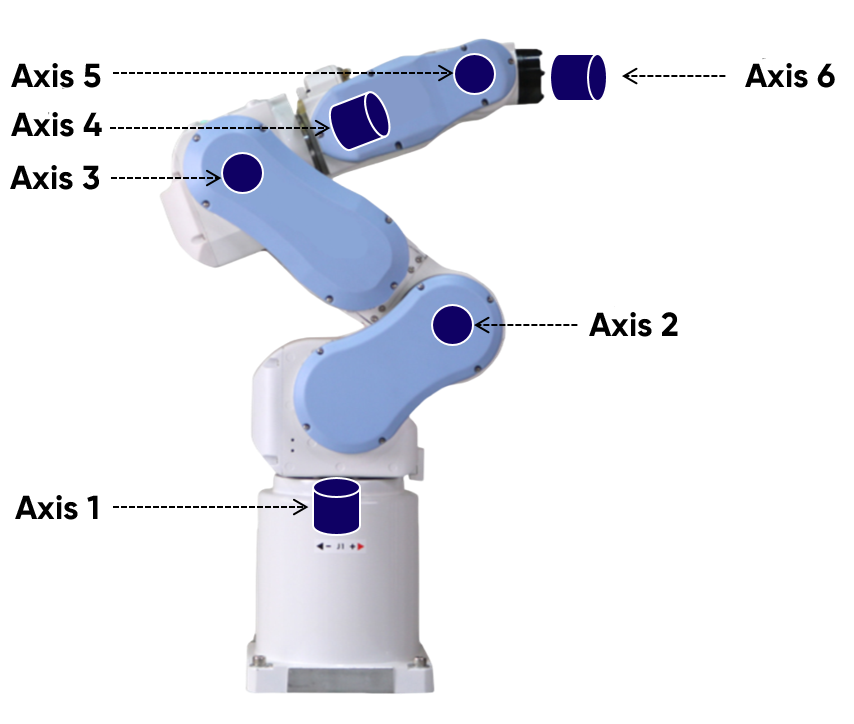

The system is built on four core components: mechanical structure, controller, drive units, and sensors. At the heart is the controller, which processes commands and precisely manages drive and mechanical systems.

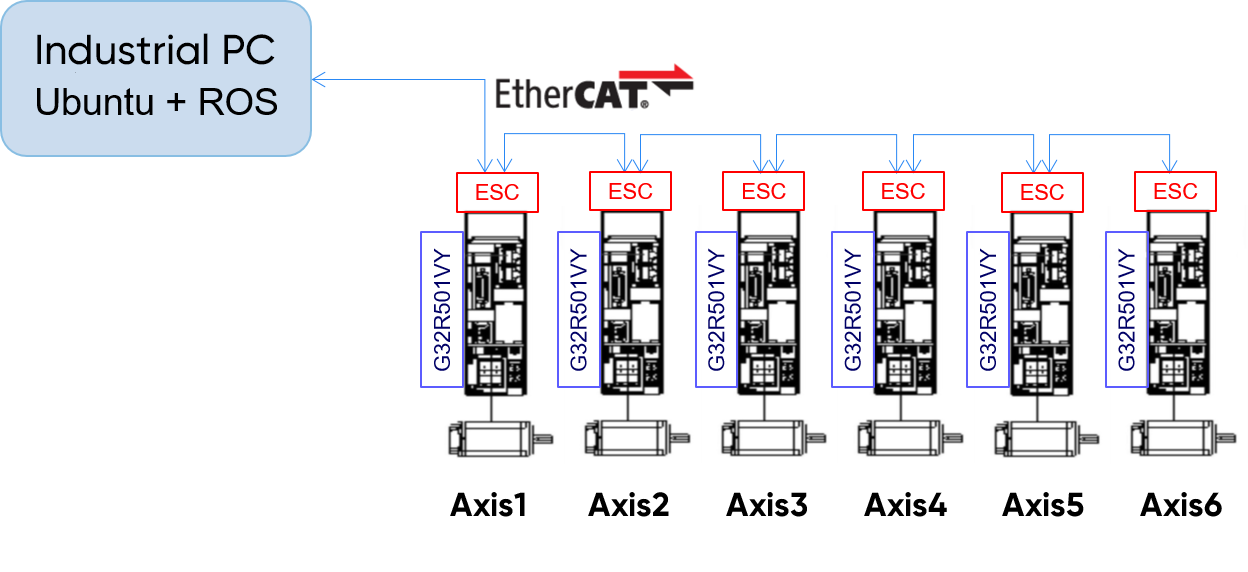

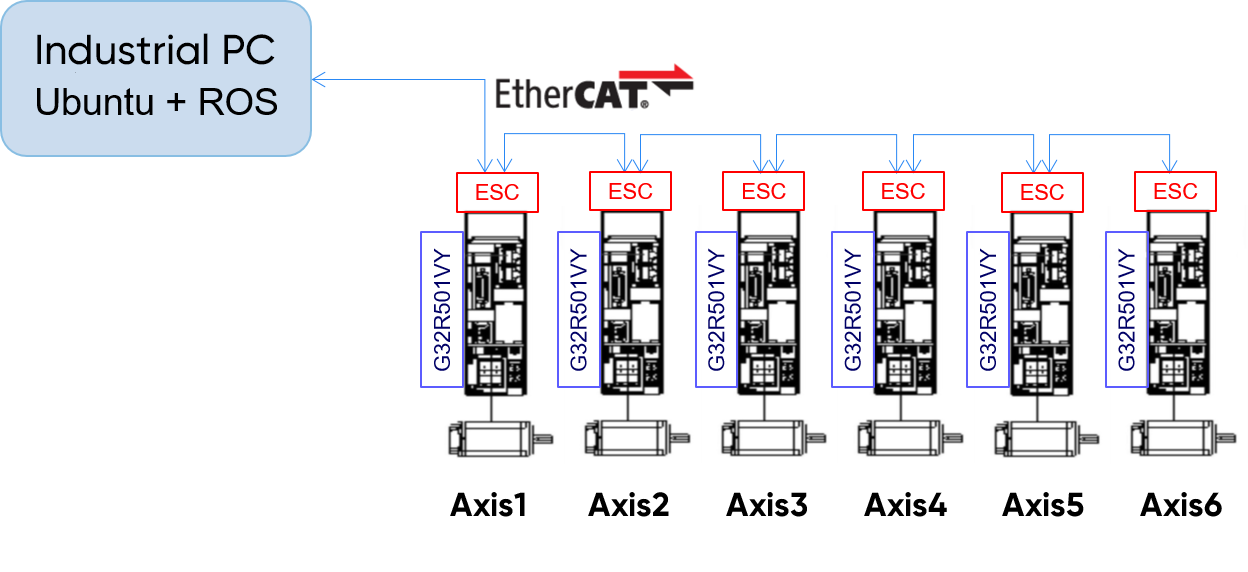

Geehy utilizes a general-purpose industrial PC running the Ubuntu operating system and the Robot Operating System (ROS) middleware as its main controller. This open-source platform enables user programmability and access to a wide range of motion control algorithms for flexible and customizable motion planning.

Real-Time Drive System

with Precise Motion Control

The robotic arm’s six joints are driven by EtherCAT bus-type high-voltage servo controllers, each powered by a G32R501 MCU for real-time feedback and control.

Peripheral control capabilities include:

· 2 pneumatic valves for gripper and suction cup control

· 2 pneumatic valves for material pushing and positioning

· 2 digital output I/Os for buzzer and indicator light

· 1 digital input I/O for material-in-place detection

· 3 digital input I/Os for emergency stop signals

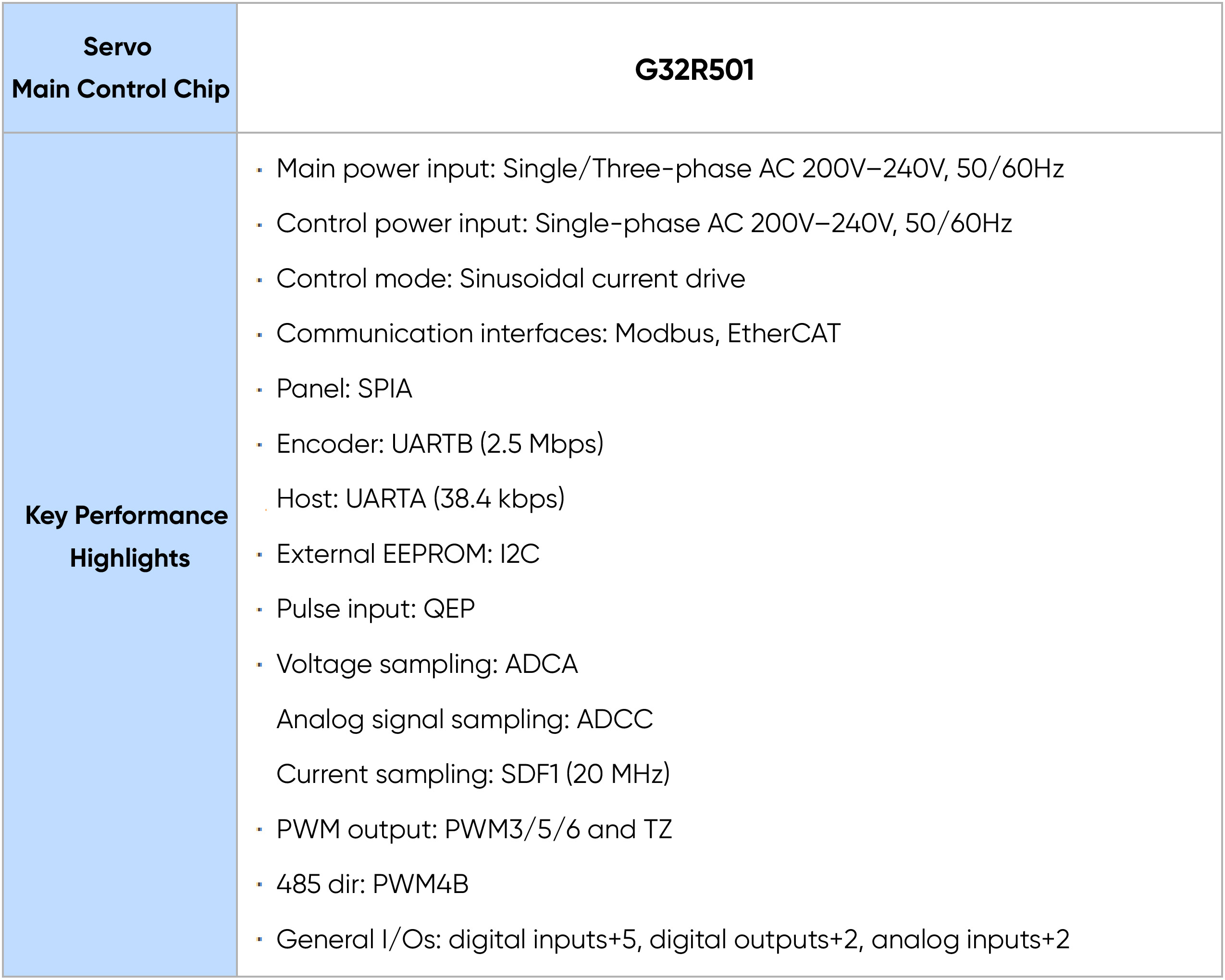

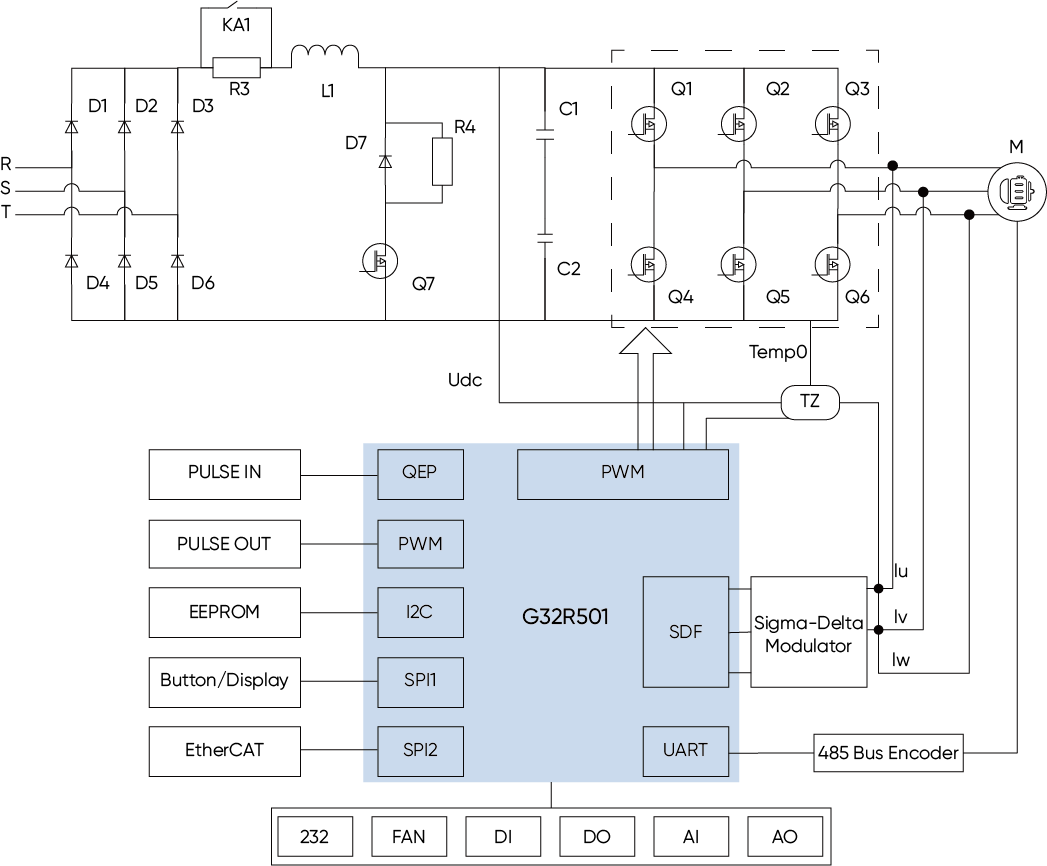

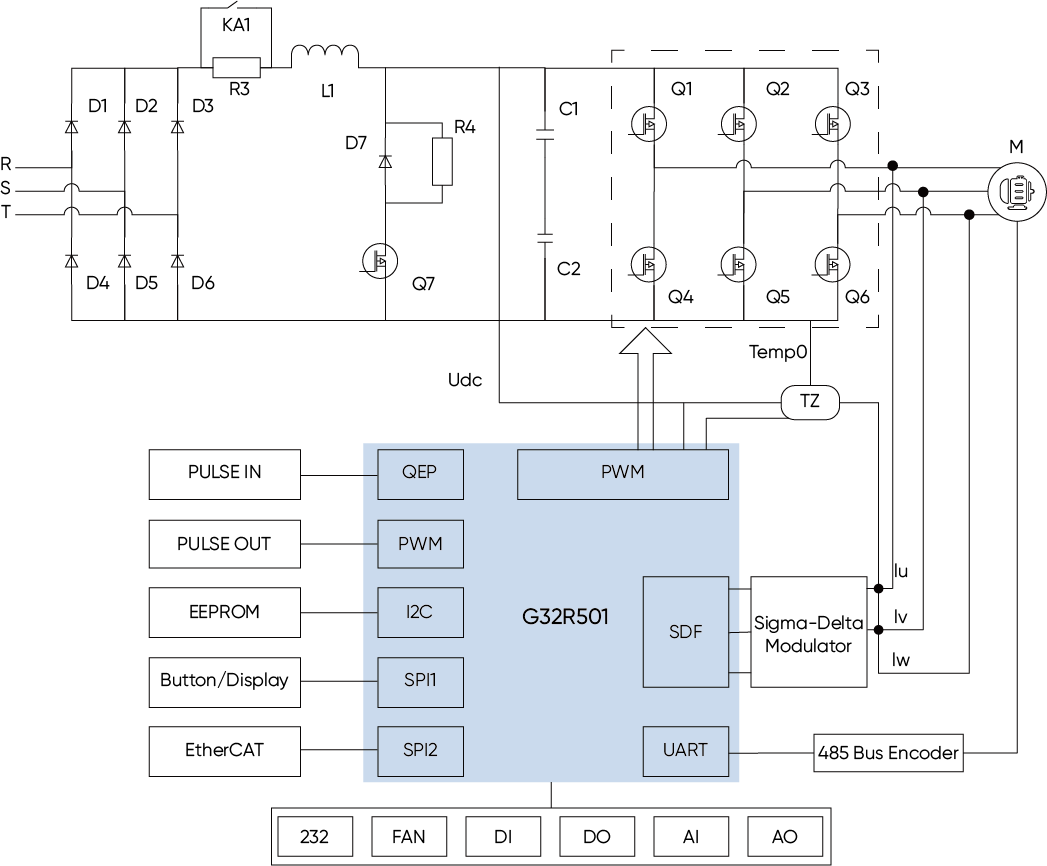

EtherCAT Bus-Type High-Voltage Servo Controller Solution

Block Diagram of the High-Voltage Servo Control System

The G32R501 real-time MCU acts as the core controller for all six servo motors, delivering fast response, efficient computing, and precise control. With microsecond-level performance and advanced motion algorithms, it keeps speed fluctuations within 0.1% during steady operation. Its main interrupt runs in about 15.8 μs, and the current loop in 0.76 μs, ensuring smooth, stable motion and high positioning accuracy—even under high speed, heavy loads, and complex trajectories.

Microsecond-Level Synchronization

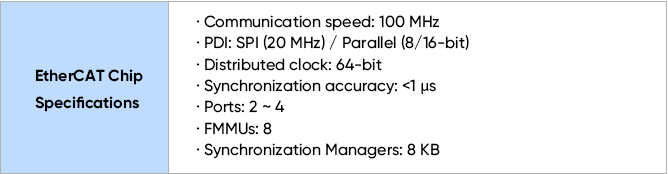

with Reliable EtherCAT Communication

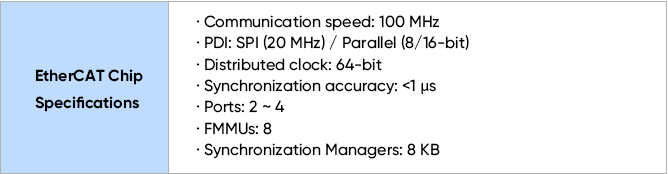

EtherCAT, a high-performance industrial Ethernet protocol, enables high-speed, high-bandwidth, and real-time communication. It supports multi-axis and multi-arm coordination with fast data exchange, precise control, and real-time monitoring. The protocol’s ring redundancy and synchronized data frames enhance communication stability and reliability in robotic applications.

In Geehy’s six-axis robotic arm system, EtherCAT enables real-time communication between the controller, servo drives, and remote I/O. The controller serves as the EtherCAT master, while the six servo controllers and one I/O module act as slaves. With a 1 ms communication cycle and <1 μs synchronization accuracy, it delivers precise, coordinated motion control.

Geehy offers a complete hardware and software servo control solution, including full-featured firmware, a proprietary PC-based debugging tool, and detailed user documentation. This enables engineers to quickly begin performance testing and further development. Keeping pace with industrial intelligence trends, Geehy continuously innovates its products, features, and performance. By building strong partnerships and fostering technological collaboration, Geehy supports shared growth across the industrial automation ecosystem.