DC brushless motors offer superior performance advantages including high efficiency, energy conservation, extended lifespan, spark-free operation, and minimal maintenance requirements. Their applications span diverse sectors such as office equipment, smart homes, consumer electronics, industrial machinery, and medical devices. With ongoing enhancements in intelligent technology and cost-effectiveness, the adoption of BLDC motors is poised to expand further, particularly in pump equipment applications.

Geehy's motor control chips are tailored to meet the diverse needs of end markets, offering rich functionality, stable performance, and user-friendly flexibility. The APM32F035 motor control dedicated MCU boasts excellent flexibility and scalability, catering to various motor control applications. It features extensive configuration options and interface standards, including pre-drive, LDO, protection circuits, and multiple communication interfaces. These capabilities streamline application peripheral circuit design and enhance system integration.

Introduction to APM32F035 220V Irrigation Pump Solution

In pursuit of cost-effectiveness and efficiency enhancement, Geehy introduces the APM32F035 220V irrigation pump solution, which incorporates enhanced anti-interference capabilities, supports constant power control, and ensures consistent water flow. It not only encompasses core motor control functions and high-performance algorithms but also prioritizes seamless integration and collaboration with peripheral components.

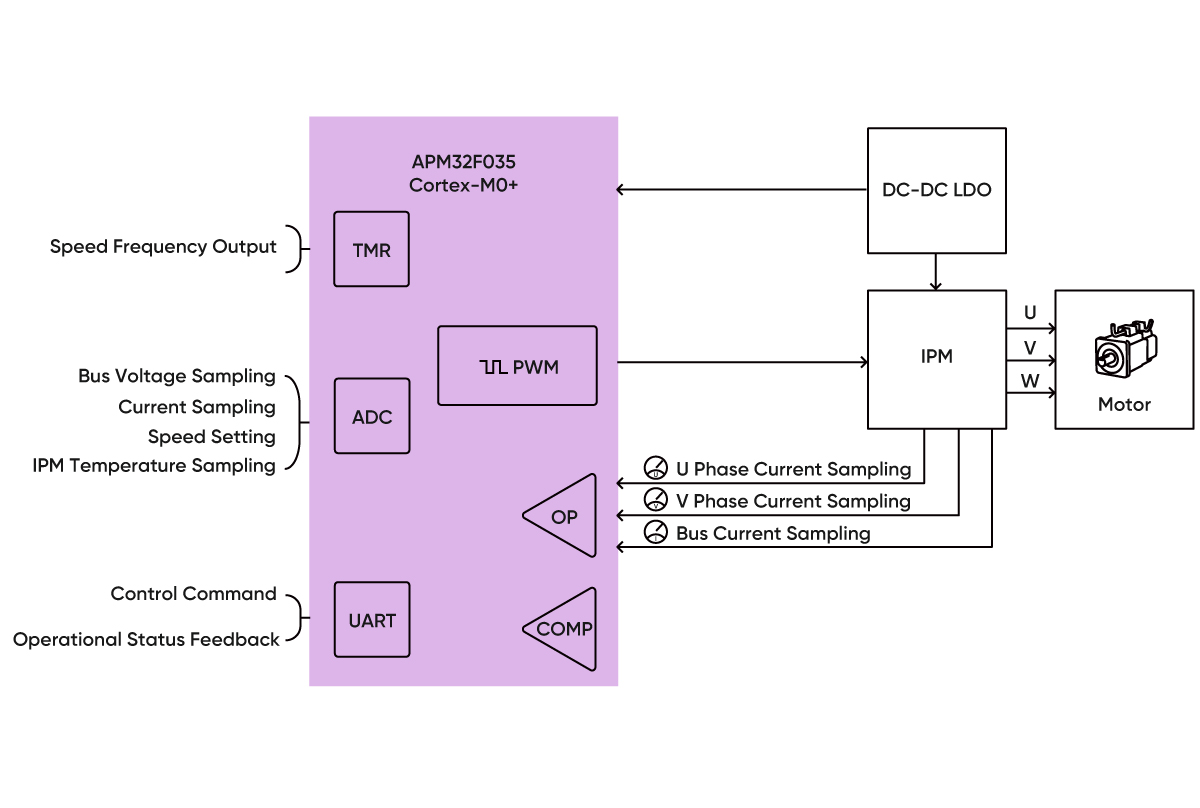

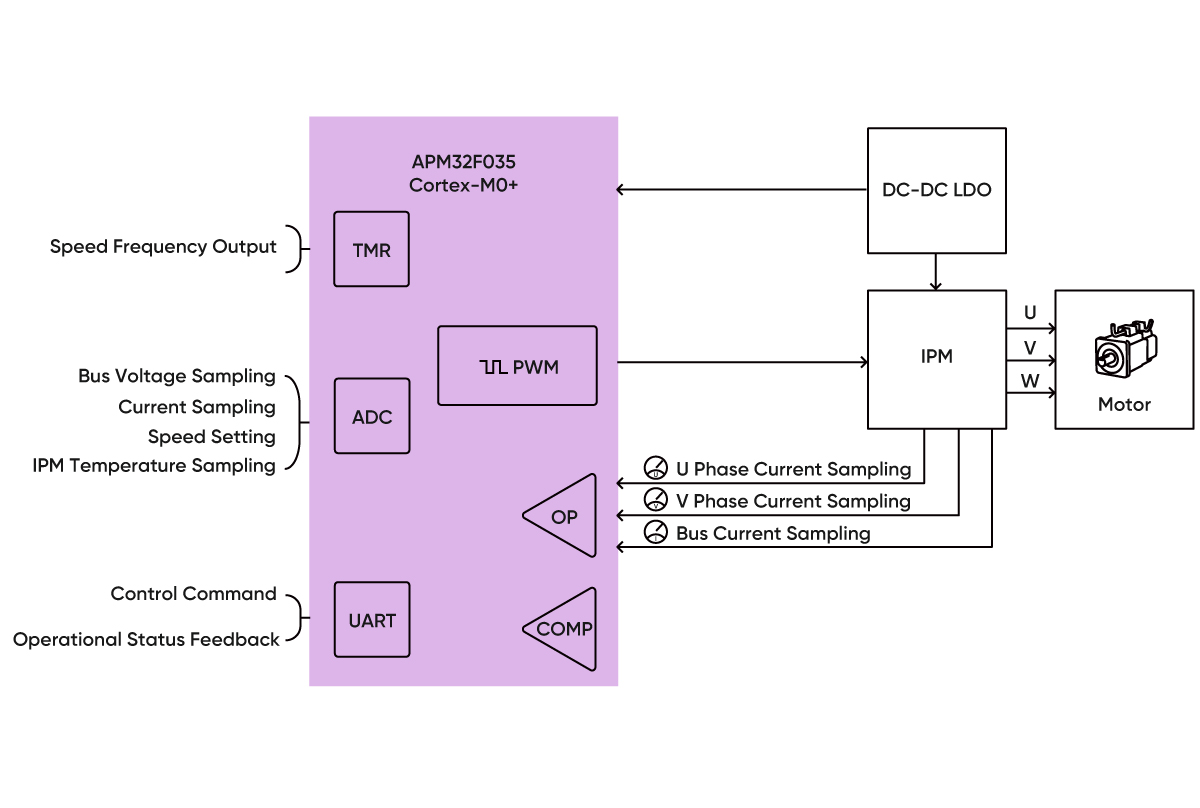

As the main control chip of this solution, APM32F035 oversees system operation and parameter adjustment, executes motor control logic and signal sampling, and receives control commands from upper-layer applications via UART. Additionally, it conducts internal motor algorithm logic control and synchronously samples bus voltage and motor phase current signals through ADC for efficient, smooth, and low-noise motor operation.

APM32F035 220V Irrigation Pump Solution Block Diagram

Features of APM32F035 220V Pump Solution

Sensorless FOC vector control for high efficiency and low noise.

Integration of multiple op-amps and comparators, simplifying circuits and reducing interference.

High control bandwidth adaptable to various load scenarios with minimal flow fluctuations.

Equipped with protection functions including water-free, over/under voltage, software/hardware overcurrent, and high IPM temperature monitoring for safe and reliable motor operation

High-speed operation to meet ultra-high lift requirements

Ultra-fast response enables quick start and stop, providing various water flow functions.

Key Advantages of APM32F035 Motor Control Dedicated MCU

Based on Arm® Cortex®-M0+ core, operating at 72MHz

Flash 64KB, SRAM 10KB, BootLoader 4KB

Built-in M0CP coprocessor, hardware configurations include shifting, 32bit/32bit division, square root, and trigonometric functions, enabling complex operations in shorter computation time

Analog peripherals: OP-AMP×4, COMP×2, 12-bit ADC×1

Digital peripherals: SPI×1, U(S)ART×2, I2C×1, CANx1, DMA

Motor-dedicated PWM supports complementary and braking functions, linkable with M0CP

The APM32F035 220V irrigation pump solution offers comprehensive development materials including software (program code), development boards, technical manuals, and SDKs. For further details, please refer to the contact information available on the Geehy official website.

Geehy remains committed to delivering advanced, dependable, and cost-effective MCUs and solutions for the motor market. In the coming year, we are set to launch new products including the APM32M3514 motor control dedicated MCU with built-in pre-drive, GHD3440 dual N-channel three-phase motor dedicated gate driver, and GHD3125R 3P+3N motor dedicated three-phase gate driver, addressing the evolving needs of motor applications.