Intelligent Absolute Encoder with Promising Market Potential

Considering application requirements, usage environment, and costs, Geehy provides two absolute encoder solutions:

1. Used in Photoelectric and Magnetoelectric Absolute Encoders

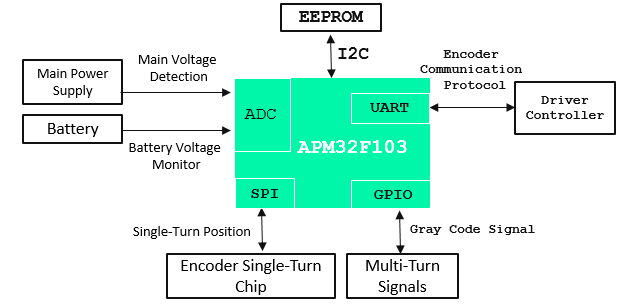

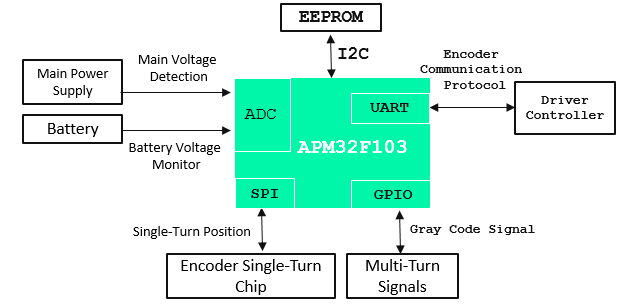

In this solution, APM32F103 industrial grade MCU is mainly used to read single-turn position, monitor voltage, calculate the number of turns and implement encoder protocol, which needs to be used with an encoder single-turn chip.

Option 1: MCU doesn’t support position calculation

2. Used in Photoelectric Absolute Encoder

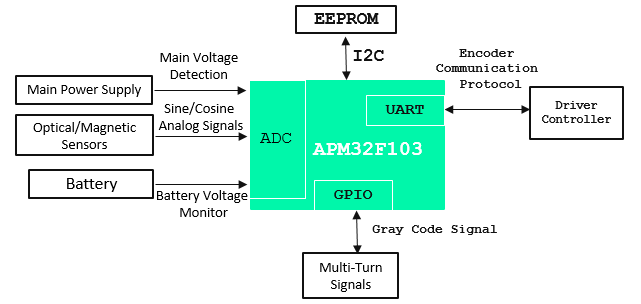

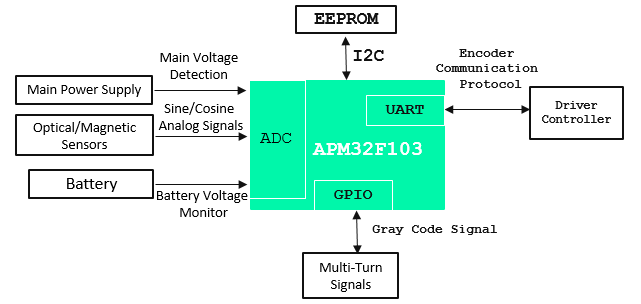

In this solution, the APM32F103 industrial-grade MCU is mainly responsible for collecting the sine and cosine analog signals from the optical and magnetic sensors, monitoring the voltage, calculating the number of turns, and implementing the encoder protocol.

Option 2: MCU supports position calculation

APM32 Absolute Encoder Solution

• Based on the industrial-grade mainstream APM32F103 MCU with Arm Cortex-M3 core

• Operating frequency 96MHz, Flash 16512KB, SRAM 6128KB

• Two 12-bit high-precision ADCs supporting 16 input channels for dynamic real-time sampling

• Two SPI interfaces with a maximum communication rate of 18Mbit/s for efficient encoder data handling

• Three USART interfaces, including USART1 with a maximum communication rate of 4.5Mbit/s, ensure high-speed and reliable encoder communication

• Flash page erase time ≤1.51ms, facilitating efficient encoder register data management

• Low power consumption of 12uA in STOP mode, ensuring prolonged battery life

• Certified IEC 61508 SIL3, meeting rigorous industrial reliability standards